Mini Post Balustrade Kits

The Mini-Post frameless glass balustrade is extremely versatile and is suitable for a variety of installations. These include low level safety railings around decking or a patio area, for internal use and on raised platforms, balconies and rooftop terraces.

A stylish yet economical alternative to the channel design, the Mini-Post offers excellent value for a frameless glass balustrade without compromising on quality or safety.

Instead of an aluminium channel, two glass brackets hold each panel in place. These are manufactured from Marine Grade 2205 Duplex stainless steel which offers superior corrosion resistance in coastal locations, or in areas with high chloride, humidity and pollution levels.

All our 10mm Glass Mini Post Balustrade & Mini Rail kits are designed to meet requirements up to 0.74kN loadings for any domestic requirements and are tested/certified to BS6180.

-

FRAMELESS MINI POST BALUSTRADE (10mm Glass)

Select options -

FRAMELESS MINI-POST BALUSTRADE (12mm Glass)

Select options -

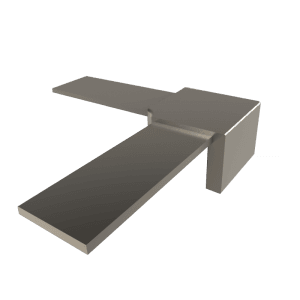

90 Degrees Mini Rail Elbow

Add To Quote -

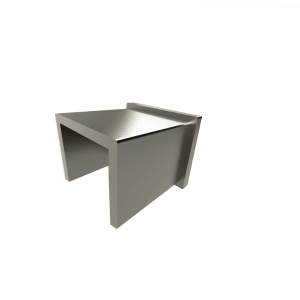

Frameless Glass Stiffener

Select options -

Mini Rail End Cap

Add To Quote -

Slotted Mini Rail (3.6m) for 10mm Glass

Select options -

Slotted Mini Rail (3.6m) for 12mm Glass

Select options