Glass Balustrade Systems

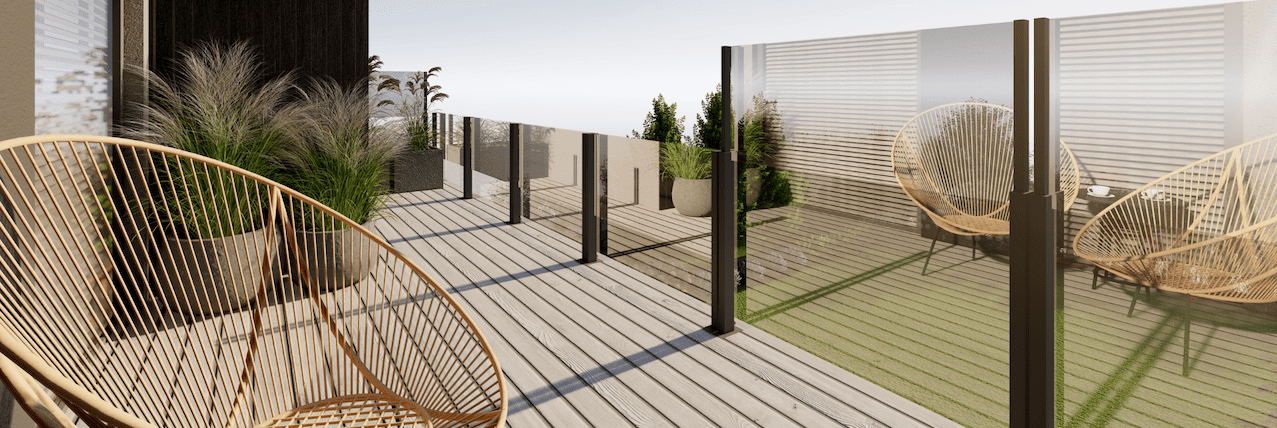

Create your perfect outdoor living space with our glass balustrade systems and glass balconies

Our glass balustrade systems are a unique style of railing featuring stainless steel handrails and component parts (via our online store ). They are designed with simplicity in mind for a glass balconies or garden decking balustrade. Elite Balustrade design each project individually to suit exact requirements. These systems are designed for fast and easy installation upon delivery. Our bespoke design and manufacture service gives you a tailored made solution to meet all your project needs.

We also offer a range of “off the shelf” solutions with fixed sized panel sizes and balustrade fixings. This includes our innovative range of Wind-Dam balustrade designs, a retractable glass wind protection system ideal for use in home dining or commercial settings such as restaurants, cafes and bars. Visit product pages below for find our more. This solution enables you to save costs on design and manufacture time if your budget is paramount.

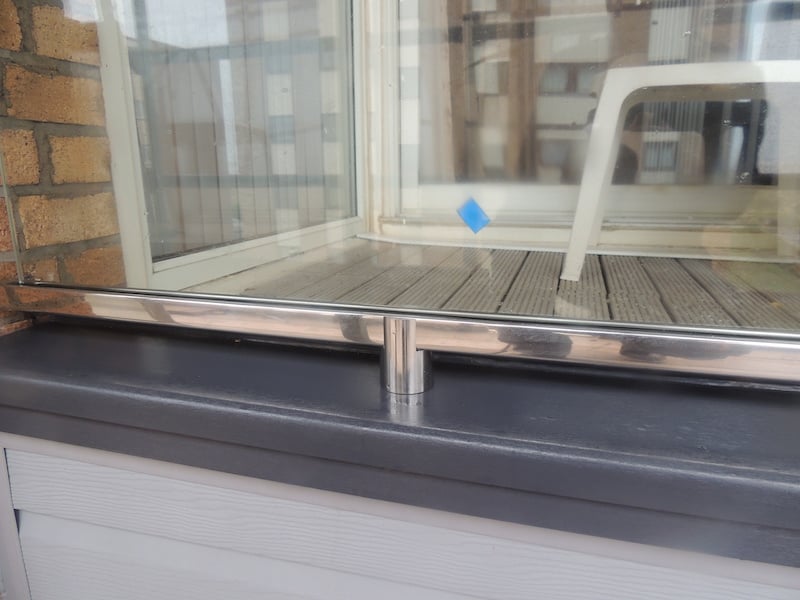

Mini Post Glass Balustrade Kits

A stylish and economical balustrade system with sleek bottom mounted stainless steel posts.

Frameless Glazing Channel - Balustrade Systems

A Frameless Glass Balustrade glazing channel design with base, edge and side mounted options.

Waterproof Membrane Balustrade Solutions

Bespoke balustrade solutions that permit installations on waterproof membrane roofing Systems

Wind-Dam Weather Protection Balustrade

Ideal for use around outdoor restaurants, hospitality and exposed external living areas

Elite Elegant Balustrade

Ideal for decking or around outdoor restaurants as cost effective windbreak or screens

Excellent Customer Service

“Just wanted to say thank you for the great service. Delivery was really prompt and a minor order issue dealt with extremely proficiently. A real nice change to have excellent customer service as fast as this. I'll certainly be returning in the future for the next phase of my renovation project.Rob Worthington

”

Completely Satisfied With The End Result

“Dear David, Jill & myself are taking this opportunity to thank you and your colleges at Elite Balustrades for a truly first class installation. This was not the easiest project to complete. Your erection team produced a truly remarkable finish of superb quality. They worked extremely hard for three days solid to make sure that we were completely satisfied with the end result. Let us assure you it is a wonderful experience watching the whole concept coming together. Thank you once again.John and Jill

”

Extremely Happy

“I was extremely pleased with the service received and the balustrade looks great. Our clients are extremely happy! I will definitely be coming back to you for future works.”Adrian Belcham